Moisture Detection in Built-Up Roof Systems: The Thermal Drone Inspection Process

Introduction

Built-up roofing (BUR) systems are a reliable choice for commercial buildings due to their robustness and longevity. However, moisture intrusion can compromise their integrity, leading to significant structural damage if not detected early. Traditional inspection methods may overlook hidden moisture, making thermal drones a valuable tool for modern assessments. This article outlines the inspection process, requirements, and specific conditions for effectively detecting moisture in BUR systems using thermal drones.

The Inspection Process

Pre-Inspection Preparation

Effective moisture detection begins with thorough preparation:

- Review Roof History: Analyze records of previous inspections, repairs, and any known vulnerabilities. This context helps target the inspection on high-risk areas.

- Weather Conditions: Schedule inspections to occur at least 24 hours after a rainstorm. This waiting period allows trapped moisture to become detectable on the roof surface. Additionally, it is crucial to choose days with wind speeds no higher than 15 mph to minimize heat transfer through convection. Conducting inspections at night further enhances visibility and improves temperature differentials.

Thermal Drone Setup

Once preparations are complete, it’s time to set up the thermal drone:

- Calibration: Properly calibrate the thermal imaging camera to suit the specific environmental conditions. Accurate calibration is essential for distinguishing temperature variances indicative of moisture.

- Flight Planning: Create a comprehensive flight plan that covers the entire roof area, accounting for obstacles such as HVAC units, vents, and parapets that could obstruct the drone’s flight path.

Data Collection

During the inspection, the drone will gather thermal images:

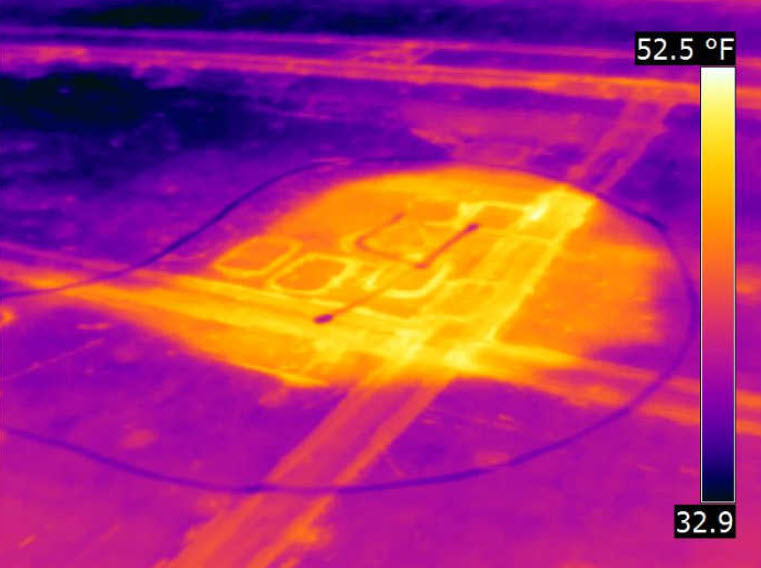

- Flight Execution: Operate the drone at a consistent altitude and speed to capture high-resolution thermal images. Ensure adequate overlap between images for thorough data coverage.

- Nighttime Operation: Conduct the inspection at night when the temperature differential is most pronounced. The cooler temperatures help enhance the visibility of moisture through thermal imaging, as damp areas will appear significantly cooler than dry sections.

Data Analysis

After collecting the thermal data, it’s time to analyze the images:

- Identifying Temperature Anomalies: Look for cooler areas in the thermal images, which typically indicate moisture accumulation beneath the roofing layers.

- Assessing Severity: Quantify the extent of detected moisture. This analysis aids in prioritizing areas needing further investigation or immediate remediation.

Reporting Findings

Compile a comprehensive inspection report that includes:

- Thermal Images: Provide high-resolution images with annotations that highlight areas of concern and potential moisture intrusion.

- Recommendations: Offer actionable insights based on the analysis, including suggestions for further evaluation or necessary repairs to address identified issues.

Requirements for Effective Inspections

To ensure a successful moisture detection inspection using thermal drones, several key requirements must be met:

- Trained Personnel: Operators should have training in both drone operation and thermal imaging interpretation. A deep understanding of both aspects is crucial for accurate assessments.

- Regulatory Compliance: Follow local regulations governing drone operation, including altitude limits and no-fly zones. Ensure that operators hold the necessary licenses for commercial drone use.

- Safety Protocols: Implement safety measures to protect personnel and equipment during the inspection. Close monitoring of environmental conditions is essential to avoid unsafe situations.

Conditions Influencing Moisture Detection

Several specific conditions significantly affect the effectiveness of thermal drone inspections:

- Post-Rain Delay: Conducting inspections at least 24 hours after a rainstorm is crucial. This waiting period allows moisture to migrate to the roof surface, making it easier to detect.

- Wind Speed Limitations: Inspections should occur in wind conditions no higher than 15 mph. High winds can create convective currents that transfer heat and obscure thermal readings, potentially leading to inaccurate assessments.

- Nighttime Inspections: Performing inspections at night enhances visibility and allows for better differentiation of temperature variations. The cooler night temperatures amplify the contrast between wet and dry areas, improving the chances of detecting moisture.

Conclusion

Thermal drones represent a modern and efficient solution for detecting moisture in built-up roof systems. By following a structured inspection process and adhering to specific conditions—such as waiting 24 hours after rainfall, limiting wind speeds to 15 mph, and conducting inspections at night—facility managers can ensure effective moisture detection. This proactive approach not only helps maintain the integrity of roofs but also prevents costly repairs, ultimately safeguarding valuable building assets. As drone technology continues to advance, the potential for improved inspection practices will only increase, making thermal drones an indispensable tool for roof maintenance.

Great content! Super high-quality! Keep it up!