As solar energy continues to grow in popularity, the need for effective maintenance and monitoring of solar panel systems is becoming increasingly important. One innovative solution is the use of drones equipped with thermal imaging technology for inspections. This method not only enhances the efficiency and accuracy of inspections but also identifies a range of issues, particularly electrical failures. This article discusses the benefits of drone-based thermal solar panel inspections, the specific problems they can uncover, and the cost implications associated with failing panels.

Benefits of Thermal Inspections

Proactive Problem Detection

Thermal inspections allow for early detection of problems, helping to prevent minor issues from escalating into major failures. By identifying temperature anomalies, operators can address issues before they lead to costly repairs or replacements.

Enhanced Energy Efficiency

Identifying underperforming panels through thermal inspections can significantly enhance the energy output of a solar system. Addressing inefficiencies promptly ensures that the system operates at its maximum potential.

Cost Savings

Investing in thermal inspections can lead to substantial long-term savings. Early intervention minimizes the risk of expensive repairs and replacements, allowing property owners to protect their investment in solar technology.

Improved Safety

Thermal inspections can identify components that are overheating, which poses fire risks. Detecting these hot spots early contributes to safer solar panel operations, giving property owners peace of mind.

Detailed Reporting

Thermal inspections generate comprehensive reports documenting the condition of solar panel systems. These reports are crucial for tracking performance over time and making informed maintenance decisions.

Benefits of Drone-Based Inspections

Enhanced Efficiency and Speed

Using drones for thermal inspections dramatically reduces the time required to assess solar panel installations. Drones can cover large areas quickly and efficiently, allowing operators to conduct comprehensive inspections in a fraction of the time it would take to do so manually.

Increased Safety

Drone inspections minimize the need for personnel to work at heights or in potentially hazardous environments. This approach reduces the risk of accidents and injuries, making the inspection process safer for workers.

High-Resolution Imaging

Drones equipped with advanced thermal cameras provide high-resolution images that can reveal even the smallest anomalies in temperature. This level of detail allows for more accurate assessments of panel health and performance.

Accessibility to Difficult Areas

Drones can easily access hard-to-reach areas of solar installations, such as large rooftops or sprawling solar farms. This capability ensures that all panels are thoroughly inspected, regardless of their location.

Comprehensive Data Collection

Drones can collect a wealth of data during inspections, allowing for thorough analysis and tracking of performance over time. This data can be invaluable for maintenance planning and financial forecasting.

Issues Identified Through Thermal Inspections

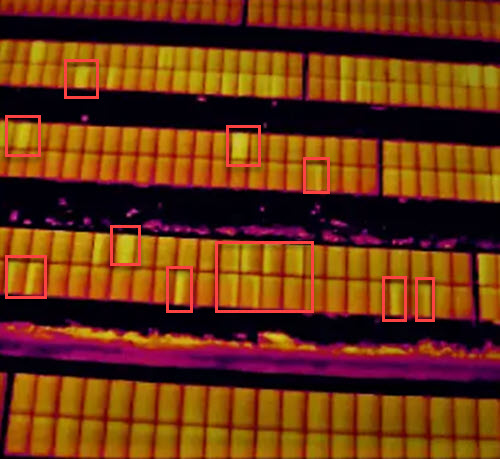

Hot Spots

Description: Hot spots are areas of a solar panel that exhibit significantly higher temperatures than surrounding areas.

Visual Identifiers:

- Appearing as bright yellow or white areas on thermal images.

Causes:

- Damage to solar cells, faulty electrical connections, or debris can create hot spots, which indicate a failure that may require immediate attention.

Module Misalignment

Description: Panels that are not optimally positioned for sunlight can experience reduced efficiency.

Visual Identifiers:

- Thermal images showing uneven temperature distribution, with some modules appearing cooler.

Causes:

- Installation errors or shifting over time can lead to misalignment, resulting in lower energy output.

Inverter Malfunctions

Description: Inverters are crucial for converting the DC power generated by solar panels into AC power.

Visual Identifiers:

- Elevated temperatures or hot spots around the inverter on thermal images.

Causes:

- Faulty components within the inverter can lead to overheating and reduced efficiency.

Shading Effects

Description: Shading from nearby trees or structures can impede sunlight access.

Visual Identifiers:

- Cooler areas that appear as dark patches on thermal images.

Causes:

- Obstructions can significantly reduce energy production by blocking sunlight.

Delamination

Description: Delamination refers to the separation of layers within a solar panel.

Visual Identifiers:

- Unusual temperature variations on thermal images, with some sections appearing cooler or hotter.

Causes:

- Moisture ingress or poor sealing can lead to delamination, negatively impacting performance.

Electrical Connection Issues

Description: Poor electrical connections can create increased resistance and overheating.

Visual Identifiers:

- Localized hot spots around junction boxes or connections on thermal images.

Causes:

- Loose or corroded connections can lead to inefficiencies and reduced system performance.

Diode Failures

Description: Diodes prevent reverse current flow in solar panels.

Visual Identifiers:

- Cold spots on thermal images, indicating areas that are not producing power effectively.

Causes:

- Failed bypass diodes can lead to energy losses and contribute to overheating elsewhere in the panel.

Reverse Polarity

Description: Reverse polarity occurs when the positive and negative wires are connected incorrectly.

Visual Identifiers:

- Abnormal temperature patterns around junction boxes.

Causes:

- Incorrect wiring during installation can lead to overheating and potential damage to components.

Ground Faults

Description: Ground faults occur when electrical current leaks to the ground.

Visual Identifiers:

- Thermal images showing unusual heat patterns near grounding connections.

Causes:

- Damaged insulation or wiring issues can pose serious safety hazards.

Interconnect Failures

Description: Interconnects link individual solar cells within a panel.

Visual Identifiers:

- Hot spots or cooler areas on thermal images indicating potential failures.

Causes:

- Physical damage or manufacturing defects can impact performance.

Cost Implications of Failing Panels

Failing solar panels can have significant financial repercussions, not only affecting the individual panels but also the entire system’s performance. Here’s how:

- Decreased Energy Production: A single malfunctioning panel can reduce the total energy output of the entire solar array. This reduction directly impacts energy savings and return on investment.

- Increased Maintenance Costs: Ignoring minor issues can lead to major failures that require expensive repairs or replacements. Regular drone inspections can help identify and address problems early, mitigating these costs.

- Extended Payback Periods: If energy production decreases due to failing panels, the time required to recoup the initial investment in solar technology can lengthen, affecting overall financial viability.

- Potential Component Replacement: Severe issues may necessitate the replacement of panels, inverters, or other components, leading to significant additional costs.

Conclusion

Drone-based thermal solar panel inspections offer a powerful solution for maintaining the efficiency and reliability of solar energy systems. By identifying a range of issues—from hot spots and electrical failures to misalignments and shading effects—these inspections provide critical insights that help optimize performance, enhance safety, and save costs. The financial implications of failing panels can be substantial, affecting energy production and overall investment returns. Embracing drone technology for thermal inspections is not just a smart move; it’s essential for maximizing the benefits of solar power and ensuring a sustainable energy future.

Do you own solar panels

Have they ever been inspected

Are they still under warranty

Do not wait until a major costly failure happens!