The Role of Drones in Cut and Fill Calculations on Construction Sites

Introduction

The construction industry has increasingly adopted drone technology for various applications, including cut and fill calculations. These calculations are essential for earthwork operations, determining the volumes of material to be excavated or added to achieve the desired landform. This article explores the role of drones in cut and fill calculations, explaining the process, benefits, methods, capabilities, and environmental impact, with a focus on Real-Time Kinematic (RTK) technology and ground control points (GCPs).

What Are Cut and Fill Calculations?

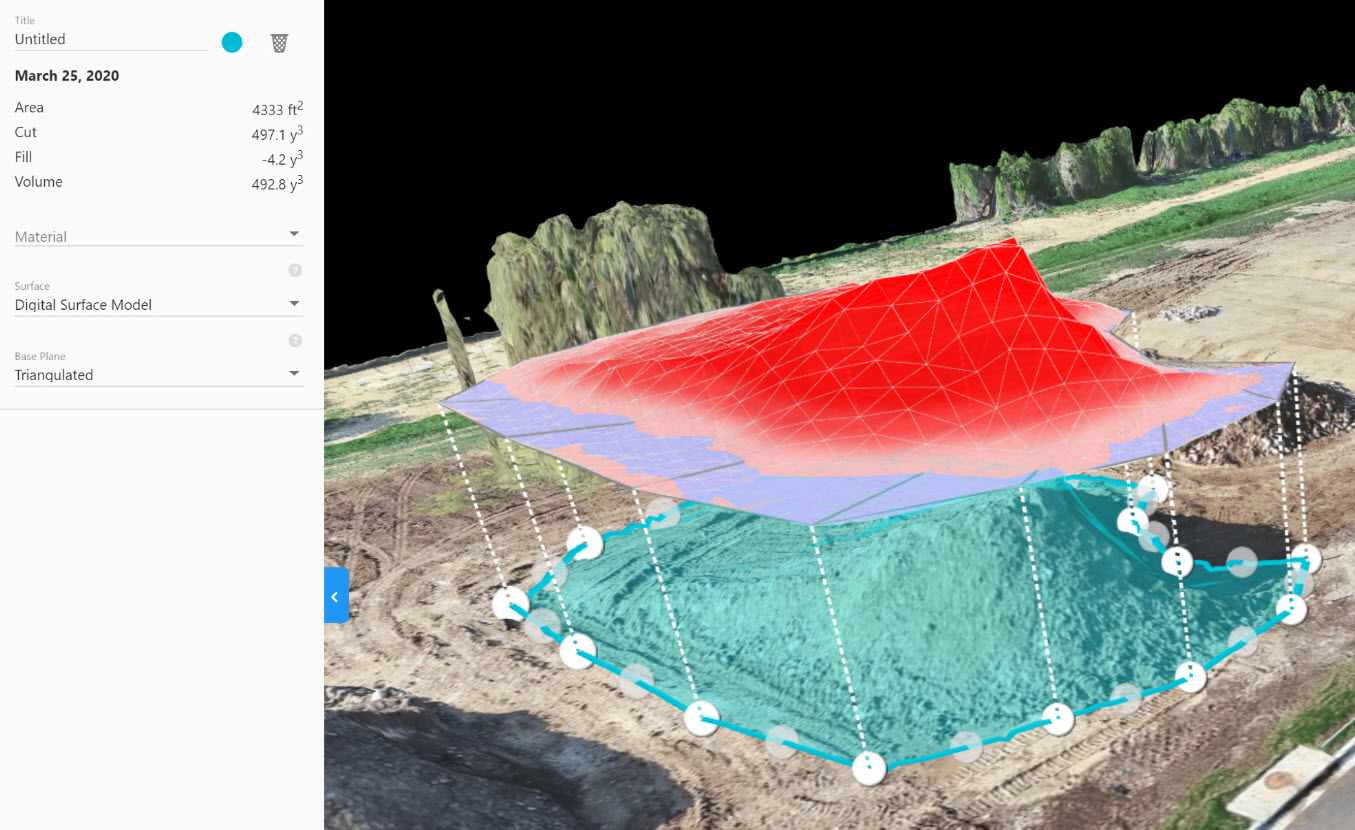

Cut and fill calculations involve determining the volumes of earth that need to be excavated (cut) or added (fill) to achieve the desired landform. These calculations are crucial for preparing construction sites, ensuring that the ground is leveled or shaped according to the project’s specifications. Accurate cut and fill calculations help in planning earthwork operations, optimizing material movement, and minimizing costs.

Benefits of Using Drones

- Enhanced Accuracy Drones equipped with RTK technology and GCPs can achieve centimeter-level accuracy in topographical data. This precision is crucial for accurate volume calculations, ensuring that projects stay within budget and on schedule1.

- Time Efficiency Traditional surveying methods can take days or weeks to cover large areas. Drones can complete the same task in a fraction of the time, allowing for more frequent surveys and real-time monitoring of the site2.

- Cost Savings By reducing the time and labor required for surveys, drones significantly lower the overall cost of the project. Accurate data also helps optimize earth movement, preventing unnecessary work and material wastage3.

- Improved Safety Drones eliminate the need for workers to access potentially hazardous areas, such as steep slopes or unstable ground. This enhances site safety and reduces the risk of accidents2.

- Comprehensive Data Collection Drones can capture data from multiple angles and elevations, providing a comprehensive view of the site. This data can be used to create detailed 3D models and maps, which are invaluable for planning and decision-making4.

Methods of Using Drones for Cut and Fill Calculations

- Photogrammetry Photogrammetry involves taking numerous overlapping photographs of the site from different angles. These images are processed to create a detailed 3D model of the terrain. This method is highly effective for capturing large areas quickly and accurately1.

- LiDAR (Light Detection and Ranging) LiDAR uses laser pulses to measure distances to the ground. This method is particularly useful for capturing detailed elevation data, even in areas with dense vegetation. LiDAR can produce highly accurate digital elevation models (DEMs) essential for precise cut and fill calculations2.

- RTK (Real-Time Kinematic) Technology RTK technology enhances the accuracy of GPS data by using a fixed base station and a rover to provide real-time corrections. This results in centimeter-level accuracy, which is critical for precise volume calculations3.

- Ground Control Points (GCPs) GCPs are known coordinates placed on the ground and used to georeference aerial data. They improve the accuracy of drone surveys by providing fixed reference points for data alignment4.

Capabilities of Drones in Cut and Fill Calculations

- Real-Time Data Processing Modern drones are equipped with software that allows for real-time data processing. This capability enables construction teams to make immediate decisions based on the latest site data.

- Integration with CAD and BIM Software Drone data can be easily integrated with Computer-Aided Design (CAD) and Building Information Modeling (BIM) software. This integration allows for seamless planning and execution of construction projects3.

- Frequent Monitoring and Reporting Drones enable frequent monitoring of the construction site, providing up-to-date information on the progress of earthwork operations. This frequent reporting helps in identifying and addressing issues promptly2.

Comparison of Traditional Methods and Current Methods Using Software

- Traditional Methods Traditional methods of cut and fill calculations often involve manual surveying techniques such as the grid method and cross-section method. These methods require significant time and labor, and they are prone to human error2.

- Current Methods Using Software Modern software tools, combined with drone technology, offer significant advantages over traditional methods. Software such as EarthCalc and Propeller Aero provide automated calculations, high accuracy, and the ability to process large datasets quickly3. These tools also integrate with CAD and BIM software, enhancing project planning and execution.

- Potential Cost and Time Savings The use of drones and modern software can lead to substantial cost and time savings. Drones can survey large areas in a fraction of the time required by traditional methods, reducing labor costs and project timelines. Additionally, the high accuracy of drone data minimizes the risk of costly errors and rework4.

Environmental Impact

- Reduced Carbon Footprint Drone surveying minimizes the need for ground vehicles and heavy machinery, significantly reducing fuel consumption and carbon emissions. This is particularly beneficial during the earthworks stage, where precise cut and fill measurements help keep the movement of heavy machinery to a minimum1.

- Non-Invasive Surveying Traditional survey methods can disrupt natural ecosystems through the need to cut sight lines and make room for survey crews. In contrast, drones can quickly and quietly capture highly accurate images without disturbing surrounding habitats and species1.

- Minimized Soil Erosion and Vegetation Loss Accurate cut and fill calculations help minimize the amount of earthwork required, reducing soil erosion and loss of vegetation. This careful management of earth movement helps preserve the natural environment3.

- Sustainability and Resource Efficiency By providing precise data, drones help in efficient planning and execution, reducing the need for rework and conserving resources. This aligns with sustainability goals and reduces the ecological footprint of construction projects4.

Conclusion

The use of drones in cut and fill calculations offers numerous benefits, including enhanced accuracy, time efficiency, cost savings, improved safety, and comprehensive data collection. The methods and capabilities of drones, such as photogrammetry, LiDAR, RTK technology, and ground control points, further enhance their utility in construction projects. Additionally, the environmental benefits of using drones, such as reduced carbon footprint and minimized ecological disruption, make them an essential tool for sustainable construction practices.

References

- Propeller Aero. (n.d.). Calculating Cut and Fill Quantities on Your Construction Site. Retrieved from Propeller Aero

- Hammer Missions. (2023, August 15). How to Calculate Stockpile Volumes (Cut/Fill) using Drones. Retrieved from Hammer Missions

- Blue Falcon Aerial. (n.d.). Boosting Efficiency and Safety: Drones in Construction Site Mapping. Retrieved from Blue Falcon Aerial

- Volatus Aerospace. (n.d.). Cut Fill Surveying. Retrieved from Volatus Aerospace

- The Drone Life. (2024, January 18). Drone Construction Earthwork Surveys: The Complete Guide. Retrieved from The Drone Life

Please tell me more about your excellent articles